黑光灯三防漆的透明涂层与涂敷验证

三防漆的透明涂层与涂敷验证

UVA光对于验证和确保涂层和固化工艺的有效性至关重要。这在汽车、印刷和电子等行业尤为重要。UVA灯用于荧光检测,以确认涂层覆盖均匀且是否附着于基材。

UVA黑光灯用于检查贴合涂层(涂覆于电子元件上的涂层),以确保覆盖均匀,并检查涂层是否有空隙或部分未能充分粘附。

UVA荧光材料或颜料常被添加到涂层中,以提高其在UVA光下的可见度,便于视觉评估,检查涂层的均匀性和质量。这些在验证印刷电路板的透明涂层时尤其有用。

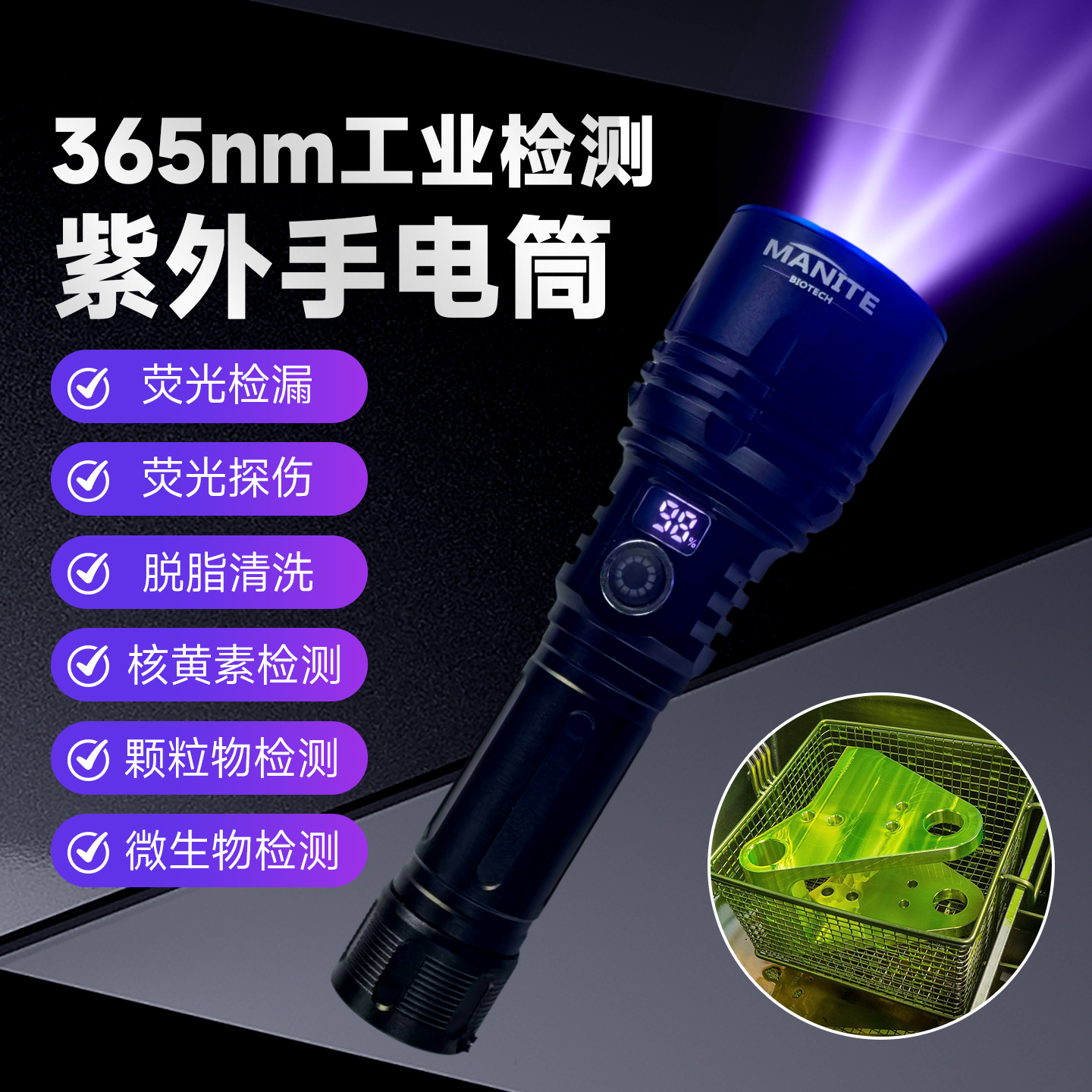

产品推荐:LUV-365系列手持式大面积紫外灯

Clearcoat and Curing Validation

UVA light is crucial in validating and ensuring the effectiveness of coating and curing processes. This is particularly important in industries such as automotive, printing and electronics. UVA lights are used for fluorescent inspection to confirm uniform coating coverage and adherence to the substrate.

UVA blacklights are used to inspect conformal coatings (coatings applied to electronic components) to ensure even coverage and to check for voids or areas where the coating may not have adhered properly or well enough.

UVA fluorescent materials or pigments are often added to coatings to enhance their visibility under the UVA light, making the visual assessment easier to check the uniformity and quality of the coating. These are particularly useful when validating clearcoats on printed circuit boards.